- +16232949412

- kent@grossmachining.com

- 24/7 Hours

xExpertly crafted solutions designed for your specific needs and industry requirements.

Our experienced professionals ensure flawless execution with a focus on detail and quality.

We handle fast-turn repairs so your work doesn’t stop.

We’re equipped for short runs and complex, single-part builds.

We recreate components from samples, sketches, or broken pieces.

Every part is measured and machined to exact dimensions.

We polish, grind, and finish parts for smooth, lasting performance.

You speak with real machinists—not a call center.

Find answers to the most common questions and concerns about our services and processes. Our FAQ section provides clarity and helps you understand how we can support your needs effectively.

Yes. We often thread, machine, and weld within a single project so the part fits, functions, and holds up.

Designed with ❤️ by Millennial Money Marketing

customer, machine, manufacturing, machine shop, automation, milling, machining, llc, customer satisfaction, metal, quality management, steel, plastic, prototype, customer service, quality management system, energy, inspection, spindle, cnc milling, machining solutions, highest quality, precision, quality policy, high level, cnc automation, automation machine, cnc solutions, automated manufacturing equipment, automated packaging machinery, policy, stainless steel

What are the primary machining technologies?

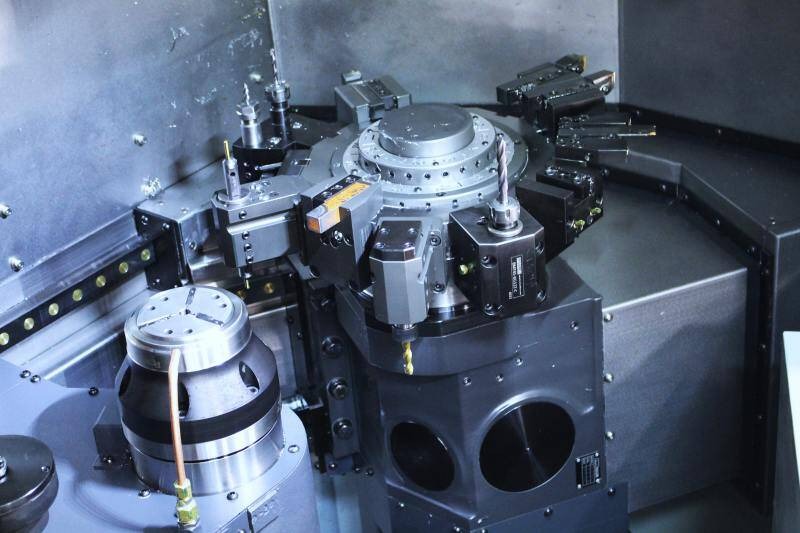

The primary machining technologies we offer include turning, threading, boring, drilling, grinding, and welding to fabricate a wide range of custom parts and components.

How can I enhance my machining expertise?

Enhancing your machining expertise can be achieved through continuous learning, hands-on experience, and staying up-to-date with industry advancements. Engage in training programs, attend workshops, and seek mentorship from experienced machinists to expand your skillset.

What defines advanced machining solutions?

Advanced machining solutions are defined by the ability to produce highly precise, complex, and customized parts through the use of advanced technologies, skilled craftsmanship, and a commitment to innovation.

How do machining solutions improve efficiency?

Machining solutions improve efficiency by enabling precise and consistent manufacturing of parts, reducing waste, and optimizing production processes, ultimately enhancing overall productivity and cost-effectiveness.

What trends are shaping machining technology?

Trends shaping machining technology include increased automation, integration of digital technologies, advancements in materials and tools, and a focus on sustainability and environmental impact.

How is automation impacting machining solutions?

Automation is transforming machining solutions by improving precision, efficiency, and productivity. It enables faster processing, reduced human errors, and enhanced consistency in manufacturing high-quality parts and components.

What innovations optimize machining processes?

Innovations that optimize machining processes include computer-controlled machines, advanced cutting tools, and real-time monitoring systems, which improve precision, efficiency, and quality of machined parts.

Can machining solutions ensure tighter tolerances?

Machining solutions can ensure tighter tolerances by utilizing advanced techniques and equipment to produce parts with exceptional precision and accuracy, meeting the most stringent specifications.

What role does software play in machining?

Software plays a crucial role in modern machining by enabling computer-aided design (CAD), computer-aided manufacturing (CAM), and computer numerical control (CNC) technology, which enhance precision, efficiency, and flexibility in the manufacturing process.

How do environmental factors influence machining choices?

Environmental factors, such as temperature, humidity, and air quality, can influence the selection of machining processes, tooling, and materials to ensure optimal performance, precision, and surface finish of the final product.

machining phoenix, phoenix machining, engine machine shop near me, gross machine shop, phoenix precision machining, crankshaft grinding phoenix az, precision machine shop near me, machine shop surprise az, phoenix machine shop, machine shop phoenix, on site machining services, machine shops in phoenix, on site machining

At Gross Machining, we pride ourselves on offering a wide range of machining services to cater to the needs of various industries. From turning and threading to precision grinding and welding, we have the expertise and equipment to handle diverse machining requirements. Whether you need one-off prototypes or small to medium runs of machined parts, our team is committed to delivering top-quality products with attention to detail.

In addition to our machining capabilities, we also provide comprehensive design services to ensure that your parts are crafted to your exact specifications. Our skilled technicians can create fully dimensioned drawings to bring your ideas to life. With a focus on precision and customer satisfaction, we strive to exceed your expectations and deliver customized solutions that meet your business objectives.