Skip to contentFrom custom threads to complete rebuilds, we deliver expert results.

Call Gross Machining today to get the part you need—fast..

Our machine shop works with a craftsman’s mindset and a technician’s accuracy. Every piece we make is shaped by careful planning and hands-on skill. From setting up the job to the final polish, we pay attention to the details. We don’t rush work out the door. Instead, we make sure each part is just right. Whether it’s a threaded rod or a custom shaft, we measure, check, and finish every part with pride. Our focus is quality over quantity, every time. That’s what makes us a machine shop Phoenix customers count on.

We focus on three services that solve the most common machining needs.

We specialize in solving problems that require more than off-the-shelf answers. If a part broke, doesn’t exist anymore, or was never mass-produced, we’ll make it. Using reverse engineering, manual inspection, and precision tools, we create solutions where others can’t. We don’t need fancy CAD files—just a sample, a sketch, or even a conversation. Our work includes one-off fittings, rare thread forms, and specialty parts for custom equipment. When larger shops say no, we take the challenge. We’re the shop people call when it’s hard, urgent, or completely unique.

We know that time, quality, and communication matter most. Here’s what sets us apart:

At Gross Machining, we don’t just serve Phoenix—we support the surrounding business community with fast, accurate, and dependable machining services. Whether you need one custom part or ongoing help with repairs and small-batch production, we’re here to help. Our team works with companies across different sectors, from heavy equipment to specialty manufacturing.

We proudly serve businesses in:

Need help with a damaged part, custom thread, or missing component? Let’s talk. We’re ready to machine a fast, reliable solution—built just for you.

machine, customer, manufacturing, machine shop, automation, milling, llc, machining, customer satisfaction, metal, quality management, customer service, steel, medical device, plastic, prototype, quality management system, energy, inspection, spindle, precision, cnc milling, quality policy, precision machining, machining solutions, automation machine, robot machine tending, automated manufacturing equipment, automated packaging machinery, dn solution, dnsolutions, stainless steel

Frequently Asked Questions

How can I improve my machining skills?

Improving your machining skills involves continuous practice, learning from experienced machinists, and staying up-to-date with the latest machining techniques and technologies. Regular hands-on experience, attending training workshops, and reading industry-related publications can significantly enhance your machining proficiency.

Can I make my own bubble machine solution?

You can make your own bubble machine solution by mixing water, dish soap, and glycerin or corn syrup. This homemade solution can be used in a DIY bubble machine to create long-lasting, large bubbles.

Are sparse solutions good for machine learning?

Sparse solutions can be beneficial for machine learning as they reduce model complexity, improve interpretability, and mitigate overfitting by focusing on the most important features.

Can I use a different descaling solution for my coffee machine?

Using a different descaling solution for your coffee machine is generally not recommended, as it may not be compatible with the machine and could potentially cause damage. It is best to use the descaling solution recommended by the manufacturer of your coffee machine.

How do I make a saline solution for my steam machine?

To make a saline solution for your steam machine, mix one teaspoon of salt with one cup of warm water until the salt is fully dissolved.

How do I make a carpet cleaning solution for a machine?

To make a carpet cleaning solution for a machine, combine warm water, a small amount of mild detergent, and a carpet cleaning solution formulated for machine use. Mix the ingredients well before applying to the carpet.

Can you use a substitute cleaning solution for a SoClean machine?

Using a substitute cleaning solution for a SoClean machine is not recommended, as it may damage the machine or affect its performance. The SoClean machine is designed to work with the specific cleaning solution provided by the manufacturer.

Can you make your own carpet cleaner solution for a machine?

Yes, you can make your own carpet cleaner solution for a machine. A simple homemade solution of warm water, mild detergent, and white vinegar can effectively clean carpets when used with a carpet cleaning machine.

How to clean abrasive solution from a machine?

Cleaning abrasive solution from a machine involves flushing the system with a compatible solvent, followed by thorough rinsing to remove any residual solution. This process helps maintain the machine's performance and prevents damage from the abrasive material.

Can you use vinegar as a cleaning solution for soda machines?

Using vinegar as a cleaning solution for soda machines is a viable option. Vinegar is an effective, natural cleaner that can help remove built-up residue and disinfect the machine's interior.

machine shop near me, machine shop phoenix, machining phoenix, machine shops near me, professional machine shop phoenix az, machine shop, custom fabrication phoenix az, high precision custom machining near me, cnc machining arizona, cnc machine shops near me, machine shops in phoenix, machine shops phoenix az, cnc machining phoenix

Our Precision Machining Capabilities

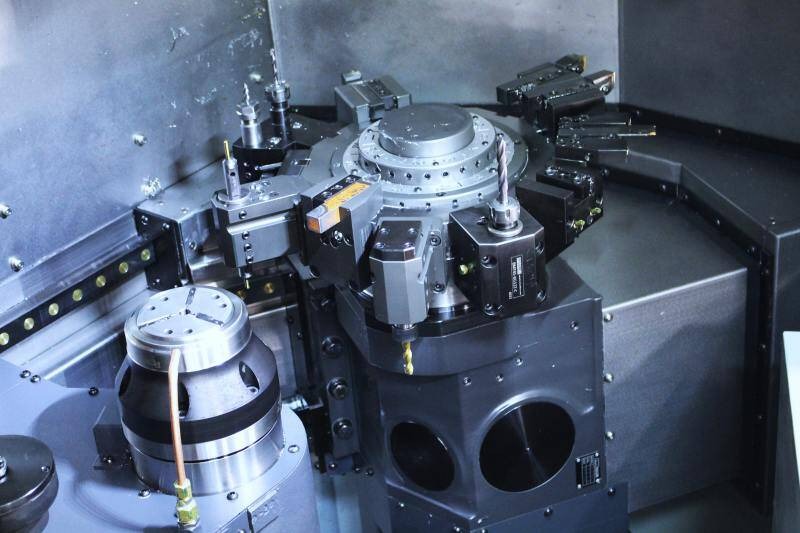

At Gross machining, we pride ourselves on our precision machining capabilities. With a team of highly skilled machinists and state-of-the-art equipment, we are able to deliver high-quality machining solutions for a variety of industries. Whether you need cylinder turning, taper turning, or custom grooving, we have the expertise to meet your needs.

Quality Assurance and Customer Satisfaction

At Gross machining, quality assurance is at the forefront of everything we do. We follow strict quality control measures throughout the machining process to ensure that each part meets our exacting standards. Additionally, our customer-centric service ensures that your needs are always our top priority. From initial consultation to final delivery, we strive to exceed your expectations and provide a seamless experience.